Process Design and Technology Integration in Operations

Table of Contents

The Integration of Process Design and Technology in Operations at Tumandok Crafts Industries ( TCI ): A Case Study

Tumandok Crafts Industries (TCI) exemplifies a successful integration of process design and innovative technology within the handicraft sector. By leveraging sustainable indigenous materials alongside contemporary production techniques, the company addresses the rising demand for eco-friendly products and nurtures local craftsmanship. Their strategic export initiatives and collaborations with local markets illustrate a robust operational model that could serve as a prototype for similar enterprises striving for domestic and international growth.

Overview of Tumandok Crafts Industries (TCI) [ Process Design and Technology Integration in Operations ]

Founded in Bacolod City in October 1988 by Ms. Josephine “Jojie” Locsin, Tumandok Crafts Industries began as a micro-enterprise registered with the Philippines Department of Trade and Industry (DTI). Initially, it focused on buying and selling homemade handicrafts during a challenging period marked by the sugar industry crisis in Negros Occidental. Jojie aimed to provide additional income and hope to displaced sugar workers by creating a market for their handicrafts. Joining the Association of Negros Producers (ANP) in its founding year enabled Tumandok to participate in workshops that encouraged the production of artisanal products such as bags, buri furniture, hand-painted wall decor, and terracotta figurines. This engagement expanded their product line and increased employment opportunities within the community. In 1997, Tumandok established its lamination factory in Barangay Central Ma-ao, Bago City, starting with just twelve workers and an initial capital of ₱50,000. This expansion marked a significant milestone in their journey towards becoming a key player in the handicraft industry.

Process Design: Emphasis on Sustainability [ Process Design and Technology Integration in Operations ]

Sustainability is central to Tumandok’s production processes. The company prioritizes local sourcing to reduce carbon emissions associated with transportation and bolster the local economy. One notable innovation is the upcycling of coconut lumber, typically regarded as waste, into valuable raw materials. This practice exemplifies an effective circular economy model, where materials are reused to create new products that align with global environmental initiatives aimed at waste reduction. Tumandok’s commitment to sustainability extends beyond materials; it encompasses ethical labor practices that support local artisans. By maintaining these principles, Tumandok meets customer expectations and resonates with consumers increasingly concerned about environmental impact.

Technological Integration: Lamination and Craftsmanship [ Process Design and Technology Integration in Operations ]

Incorporating advanced lamination technology enhances durability and aesthetic appeal in Tumandok’s products. The company creates visually appealing and resilient items by layering indigenous materials with a resin finish. Skilled artisans blend traditional techniques with modern production methods to ensure exceptional quality in each handcrafted piece. Additionally, Tumandok employs powdered stone technology, which utilizes by-products like sawdust, rice hulls, and charcoal, further contributing to sustainability by minimizing waste and optimizing resource utilization. This innovative approach allows Tumandok to produce unique items while adhering to eco-friendly practices.

Market Engagement: Dual Focus on Local and International Sales [ Process Design and Technology Integration in Operations ]

Tumandok Crafts Industries strategically positions itself across diverse markets, balancing local availability with international outreach. Their products are available in prominent local retail outlets such as Kultura and the OTOP outlet in Negros Occidental, providing easy access for local consumers. Furthermore, their active export operations showcase Filipino craftsmanship globally, enhancing market penetration. The company’s participation in events like the Negros Trade Fair highlights its commitment to community engagement while promoting its products. This diversification reduces reliance on any single market while bolstering business resilience amid fluctuating global demand.

Social Responsibility: Supporting Local Communities [ Process Design and Technology Integration in Operations ]

Social responsibility is integral to Tumandok’s operations and profit generation. The launch of the Haiyan Collection, created in response to Typhoon Yolanda, embodies their commitment to community support by providing job opportunities for affected artisans from Barangay Agdaliran. This initiative not only aids economic recovery but also fosters positive brand perception among ethically-minded consumers. Tumandok’s collaboration with former head designer Carlos Lanuza led to using discarded coco lumber from recovery projects as valuable resources for their product lines. This partnership illustrates how Tumandok transforms adversity into opportunity while reinforcing its dedication to social issues.

Continuous Improvement and Innovation [ Process Design and Technology Integration in Operations ]

Continuous innovation is fundamental to Tumandok’s operational strategy. The company actively monitors market trends and evolving consumer demands for sustainable products, refining its production processes accordingly. By implementing design thinking principles, Tumandok fosters new ideas, prototypes innovative offerings, and assesses market viability effectively. For instance, they plan to launch several new design lines incorporating diverse materials, such as banana fibers and sea shells, while focusing on sustainability. This proactive approach enhances adaptability and improves the company’s capacity to meet rising customer expectations while navigating industry changes.

[ Process Design and Technology Integration in Operations ]

Challenges and Future Directions

Despite its successes, Tumandok Crafts Industries faces several challenges that are typical of the handicraft sector. Fluctuating raw material costs—particularly for imported resin—alongside currency exchange impacts present financial hurdles. Competition from low-cost, mass-produced goods from international markets also affects pricing structures. To address these issues, Tumandok must continue innovating and invest in employee training to enhance artisan skills further. Exploring advanced technologies such as 3D printing could open avenues for new product lines while potentially lowering production costs. Strengthening their digital presence through e-commerce platforms will be essential for reaching broader consumer bases and maximizing brand visibility.

[ Process Design and Technology Integration in Operations ]

A Model for Sustainable Handicraft

Tumandok Crafts Industries illustrates how a commitment to sustainability, innovation, and community engagement can drive operational success in the handicraft sector. By effectively utilizing indigenous materials, integrating modern technology, and adhering to ethical practices, the company produces aesthetically pleasing products and positively impacts the local economy while promoting sustainability. Their operational strategies—including continuous improvement efforts and responsiveness to market trends—position them favorably within an evolving industry landscape, ensuring they maintain a competitive edge amid challenges. As they look toward future growth opportunities, Tumandok remains dedicated to empowering communities while delivering high-quality handicrafts that resonate with consumers worldwide.

[ Process Design and Technology Integration in Operations ]

More Stories

- Email Marketing Mastery: The Secrets to Engaging Campaigns

- The Art of Drinking Coffee: From Childhood Rituals to Global Trends

- A Brighter Future for Bacolod: Negros Power’s 5-Year Development Plan

- Bacolod’s Early Morning Brownouts: Why Fixing Hotspots Matters

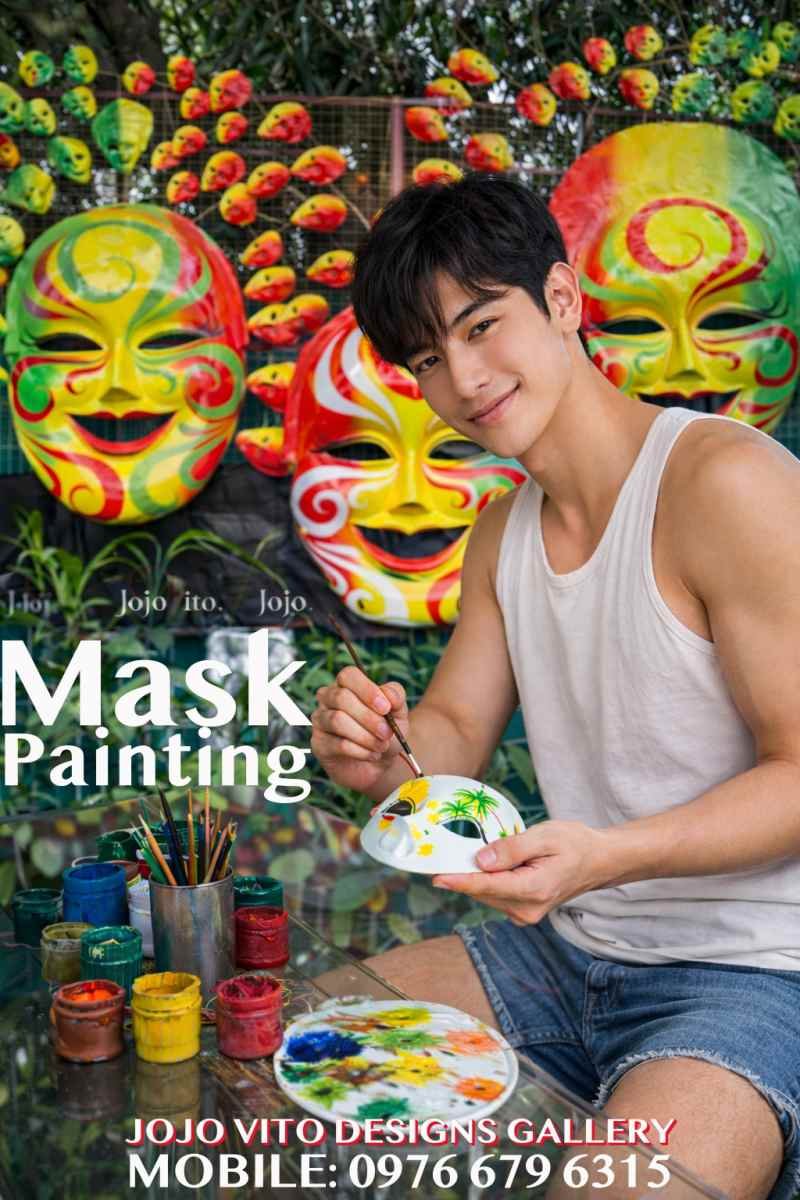

- Production, Operations, Logistics Management | Jojo Vito Designs Gallery

- Si.Pud Bar & Grill : A Review

- 20 TOP SINGAPORE TOURIST SPOTS | THINGS TO DO

- CEBU TOURIST SPOTS | THINGS TO DO

- CREMATION, A CHOICE FOR MANY FILIPINOS | Teresa Development Corporation

- 10 MEN’S FASHION HACKS | DRESS TO IMPRESS

- FOOD PRESENTATION IDEAS | THAILAND

- HOW TO STAY LOOKING YOUNG IN YOUR 40’s

- HOW TO GET RID OF BLACKHEADS

1. Analyze how the integration of advanced lamination technology has transformed Tumandok Crafts Industries’ production processes. What specific operational efficiencies and product quality improvements have resulted from this technological adoption, and how do these changes align with sustainability goals?

The production procedures of Tumandok Crafts Industries have been considerably upgraded by the use of cutting-edge laminating technology. The company has created a smooth fusion of cutting-edge technology and traditional workmanship by applying a resin finish to layers of local materials. This strategy guarantees that its products maintain their competitiveness in both domestic and foreign markets by improving both their structural soundness and visual attractiveness. Utilizing local resources and by-products, like powdered stone and coconut timber, lessens dependency on foreign inputs, which lowers costs and improves supply chain stability. This is another noteworthy benefit. By reducing the environmental impact, upcycling waste materials into raw inputs directly helps Tumandok’s commitment to sustainability. In particular, it supports its sustainability objectives by lowering its carbon footprint through local sourcing and material upcycling, which lowers emissions related to waste management and raw material transportation. Technology integration strengthens traditional artisanship rather than replaces it, guaranteeing that local artisans continue to play a part while gaining access to contemporary tools and methods. With these developments, Tumandok will continue to lead the way in producing high-quality, environmentally friendly handicrafts that satisfy customer expectations while boosting local economies and lessening its negative effects on the environment.

2. Discuss the strategies Tumandok Crafts Industries employs to incorporate sustainability into its process design. How do these strategies not only minimize environmental impact but also enhance the company’s competitive advantage in both local and international markets?

When designing its processes, Tumandok Crafts Industries takes a holistic approach to sustainability, emphasizing social justice, resource efficiency, and environmental responsibility. These tactics help the business become more competitive in both domestic and foreign markets while also lessening its environmental impact. I believe it’s mostly local sourcing since Tumandok boosts the local economy and lowers carbon emissions associated with transportation by giving preference to locally sourced commodities. This strategy reduces supply chain interruptions and improves the business’s standing in the community. Furthermore, upcycling coconut lumber turns leftover coconut lumber—which is typically considered waste—into useful raw materials for its goods. This approach reduces waste and supports international environmental goals, making it a prime example of the circular economy concept. By providing goods with genuine, sustainable origins, these methods help the business stand out from the competition and appeal to consumers who care about the environment. The durability and visual attractiveness of Tumandok’s goods are enhanced when combined with the application of cutting-edge lamination processes. This process guarantees that the goods retain their traditional character while meeting contemporary quality standards. By incorporating state-of-the-art technology, Tumandok is able to satisfy global quality requirements while preserving environmentally friendly production, making it appealing to both traditional and contemporary markets. Last but not least, Tumandok supports ethical labor standards by hiring and empowering regional craftspeople. Economic resilience is promoted by programs such as the Haiyan Collection, which offer employment possibilities to communities recuperating from natural disasters. Tumandok increases the authenticity and attraction of its brand by fusing traditional craftsmanship with contemporary.

3. Examine the role of innovation in Tumandok’s ability to adapt to changing consumer preferences and market demands. How has the company utilized design thinking principles to refine its product offerings, and what implications does this have for its operational strategy moving forward?

The ability of Tumandok Crafts Industries to adapt to changing consumer preferences and handle shifting market needs is largely dependent on innovation. They keep a close eye on consumer tastes and industry developments, especially the rising demand for premium, environmentally friendly goods. This realization motivates the business to create products that appeal to clients who care about the environment and society. Additionally, I want to stress that their use of powdered stone technology, repurposed coconut lumber, and other sustainable materials shows their dedication to meeting consumer demand for sustainable and ethical products. The company’s brand attractiveness is increased by this focus, which also supports worldwide sustainability aims. Tumandok’s image as an environmentally responsible company is cemented by the incorporation of sustainable practices through creative material use and production procedures. This puts the business in a good position both locally and internationally.

4. Identify the key challenges Tumandok Crafts Industries faces in integrating new technologies into its operations. Considering these challenges, what strategic recommendations would you propose for enhancing their process design and technological capabilities to ensure long-term sustainability and competitiveness?

As is common in the handicraft industry, Tumandok Crafts Industries may face a number of difficulties in integrating new technology into its operations. In particular, the high price of purchasing cutting-edge technologies like resin laminating equipment or 3D printing. Additionally, finances are strained and technological advancements are limited by fluctuating raw material prices, especially for imported components like resin. On the human side, artisans’ lack of technical proficiency may make it more difficult for them to successfully accept and use cutting-edge technologies. It takes time and money to train artisans to combine traditional artistry with contemporary methods. In terms of manufacturing, it’s still difficult to compete on pricing with inexpensive, mass-produced goods while preserving the sustainability and quality of handcrafted goods. Making sure that customers appreciate and comprehend the advantages of the technological innovations incorporated into products, such as their longevity and environmental friendliness, is crucial. As for suggestions, start with low-cost technological advancements like improving laminating methods or maximizing the use of current powdered stone technology, or look into grants or collaborations to finance larger expenditures in cutting-edge technologies like 3D printing. Encourage intergenerational learning among workers by blending traditional handicraft with technologically advanced approaches. Finally, improve the business’s e-commerce skills to reach a worldwide audience and lessen reliance on regional retail locations. Utilize digital channels to inform customers about the benefits of sustainable and technologically advanced products. In a sector that is changing quickly, this all-encompassing approach will set up the business for long-term success.

1. The rapid advancements in technology have significantly transformed various industries like Tumandok, by incorporating innovative solutions that aim to enhance operational efficiency and product quality. Among these technologies, the integration of advanced lamination technology enhances durability and impact in Tumandok’s products. It presents substantial potential benefits in terms of sustainability perspectives, as it can improve resource efficiency and contribute to the achievement of sustainability goals. For instance, the technology can enable the production of customized products, reduce material waste, and facilitates the use of sustainable items, all of which contribute to improved environmental performance. Furthermore, it can lead to significant advantages in terms of supply chain optimization, inventory management, and the potential for recollected and reused manufacturing, all of which align with the principles of sustainability.

2. Continuous innovation is fundamental to Tumandok’s operational strategy. Incorporating sustainability into their process design involves strategic planning that minimizes environmental impact while enhancing a company’s competitive advantage. Manufacturing smart through the use of automation like AI and data analytics will optimize workflow production to reduce errors, emissions, and waste for proper utilization of materials and energy.

When it comes to foreign markets where sustainability is becoming more valued, a sustainable supply chain can be a unique selling point. Customers appreciate companies launching initiatives to retrieve materials for recycling or remanufacturing at the end of their intended lifespan, and will also create additional income opportunities.

Additionally, Brand reputation can be improved by reducing environmental impact through recycling, repurposing, or renewing materials in production, drawing in eco-aware clients both domestically and abroad. Because they are seen as lower-risk and more suited for long-term growth, investors are becoming more interested in businesses with solid sustainability policies.

Even though there could be up-front expenses involved in designing a sustainable process, the strategy is promising in the long run due to cost savings, brand loyalty, and regulatory advantages. Businesses may create value for society, the environment, and themselves by incorporating sustainability into their process design, which will strengthen their position in the market and make them more competitive.

3. Tumandok’s capacity to adjust to evolving customer preferences and market needs depends heavily on innovation, particularly in a setting where customers place a greater importance on functionality, variation, and sustainability. Tumandok has used “design thinking principles” to improve the quality of its product offerings, which has helped the business remain relevant and competitive. The company has concentrated on using market analysis to identify client wants and pain points in order to design products that are not only visually attractive but also highly practical and sensitive to customers. For example, Tumandok may include sustainable materials into its design process in response to consumer requests for environmentally friendly materials, striking a balance between tradition and innovation. Tumandok may leverage rapid development and refinement to bring new ideas to life. It could allow them to launch products faster, staying ahead of competitors and responding to trends in real time. New product lines that can appeal to both traditionalists and modernists, depending on the market sector.

The commitment to sustainability is Tumandok’s brand story, helping the company differentiate itself in local and international markets. Ethical responsibility and commercial demand are in line when sustainable materials and manufacturing techniques used in product design. By combining traditional and modern design elements, Tumandok can cater customers who want a modern design without sacrificing the cultural depth of a product. As part of product offerings, integrating e-commerce and using online platforms for product testing and sales, the company can access a global audience and customer engagement. The availability of digital channels will enable Tumandok to enter international markets for faster scaling and higher profit margins.

Tumandok has improved the quality and market relevance of its product offerings. Moving forward, Tumandok’s operational approach will have to be concentrated on utilizing digital technologies, creating these innovations, and dedicated to sustainability and cultural relevance.

4. Integrating new technologies into operations presents several challenges. Automation, digital design tools, and e-commerce platforms, often require significant amount of investment. Examples of these are: hardware, software, training, and potential reconfiguration of existing processes. For an industry like Tumandok that may have limited resources, high initial costs can be a barrier for adaptation, especially when business is not that good. New technologies may also create resistance from employees who may be used to traditional way of manufacturing. Implement a change management plan to address resistance, explaining the benefits of technology to both the company and employees will help. Other employees may lack the necessary skills to use a new digital tools which will then be required for training and upskilling. To address this, partner with educational institutions or offer in-house training to employees like TESDA on how to operate new digital tools or automation systems. Long-term growth and innovation will be fostered by a trained and empowered workforce that can leverage technology to increase productivity and efficiency. This workforce will also be more flexible.

Tumandok should aim for a blended traditional craftsmanship with modern technology in a way to preserve cultural heritage while innovating. Moreover, balancing heritage with modern innovation can be a delicate process. Maintaining the balance is important to existing customers who values the traditional craftsmanship that Tumandok represents, potentially boosting brand loyalty. This allows Tumandok to maintain its competitive edge in both heritage and modern design markets while appealing to a broader audience.

The potential of cyber threats grows as Tumandok moves toward digitalization, especially through e-commerce and consumer data management. It becomes essential to make sure that consumer data and intellectual property are protected. Invest in robust cybersecurity software and protocols, and develop a disaster recovery plan and conduct regular security audits to identify and address vulnerabilities.

Between workforce opposition and cost, Tumandok will have a difficult time incorporating modern technologies while preserving its traditional identity. Tumandok may, however, overcome these obstacles by emphasizing cybersecurity, increasing supply chain coordination, investing in training, taking a staged approach to technology integration, balancing tradition with innovation, and utilizing data analytics. These tactical suggestions will guarantee Tumandok’s long-term viability and competitiveness in both domestic and foreign markets, in addition to improving its process design and technological capabilities.

PEARL JOY ORTIZ

MARLA C. LAURISTA

PEARL JOY ORTIZ

DBA- 106

ASSIGNMENT # 2

QUESTION NO.1

What is specific operational efficiencies and product quality improvements have resulted from this technologies adoption, and how do these aligns with sustainability goal?

ANSWER:

This is our first time heard about the Tumandok’s Crafts Industries(TCI) while we are reading the article We rally feel amaze how it started this business and it really help the local to have extra income by creating a beautiful handmade crafts.

For us good operational efficiency can help the TCI are the following:

1.) AUTOMATION (AI)- This can help the TCI employee to minimize their job during the preparation process ( washing and drying the items, cutting, buffing, and assembling the product )in this way to reduce labor costs and minimize human error .

2.) ADVANCE INVENTORY MANAGEMENT- Management software enhances tracking and forecasting to reduce excess stock. It can detect also or show which items are in low stock.

3.)PREDICTIVE MAINTENANCE- The device that able to show that the machine is needed for maintenance service already. This way it can help to extend the life span of the equipment and it will lead to reduced resource consumption and lower repair cost.

4.) ENERGY OPTIMIZING TECHNOLOGIES- Utilizing smart sensors for their machinery e.g. once their operation already reached 2hrs straight the machine will show a blinking light and it will slow down till it switches -off. and it will rest for 30mins then be able to use it again. To optimize energy use it will lead to a lower carbon footprint.

PRODUCT QUALITY IMPROVEMENT:

1.)REAL- TIME MONITORING – Technologies like sensors and machine learning allow for real-time quality control, identifying defects early in the production process. This results in higher-quality products and less waste.

2.) CUSTOMIZE PRODUCTION: Advanced manufacturing techniques, such as 3D printing, enable more precise and customized products. This not only improves customer satisfaction but also reduces material waste. The most important is that TCI able to create the design which is customer prefer.

3.) DATE-DRIVEN DECISION MAKING- Utilizing data analytics to inform design and production decisions leads to more precise product specifications. It means the TCI able to see which is items are most saleable form there they can know which product or items they will create more.

ALIGN WITH SUSTAINABILITY GOAL:

1.) REDUCE WASTE: Technologies that optimize resource use directly contribute to waste reduction, aligning with circular economy principles.

2.) LOWER – Improved efficiency in production processes leads to lower greenhouse gas emissions, supporting global sustainability initiatives.

3.) SUSTAINABLE SOURCING- Technologies that facilitate the traceability of materials ensure ethical sourcing practices, aligning with sustainability certifications and consumer preference.

4.) LIFECYCLE ANALYSIS- Advanced enables a better understanding of product lifecycle impacts, fostering continuous improvement in sustainability practices.

By adopting these technologies, Tumandok Craft Industries can achieve significant operational efficiencies and product quality improvements. These advancements not only enhance competitiveness but also align closely with sustainability goals, creating a more responsible and resilient business model. This synergy between technology, efficiency, quality, and sustainability positions the company favorably in an increasingly eco-continuous market.

TCI by leveraging these technologies, organizations not only enhance operational performance and product quality but also contribute to broader environmental and social goals, creating a more sustainable future.

QUESTION NO2:

Discuss the strategies Tumandok’s Crafts Industries employs to incorporate sustainability into its process design. How do these strategies not only minimize environmental impact but also enhance the company’s competitive advantage in both local and internation market?

ANSWER:

Tumandok’s Craft industries employs several strategies to incorporate sustainability into its process design, which not only minimize environmental impact but also enhances its competitive advantage in both local and international market.

1.) SUSTAINABLE SOURCING- Tumandok’s craft industries need to prioritize the use of renewable and locally sourced materials, such as bamboo, seashell recycled products, etc. By following this approach for sure there is a benefit that the TCI and customers will gain by reducing the carbon footprint associated with transportation and supporting local economies, appealing to consumers who value ethical sourcing.

2.) ENERGY-EFFICIENT PRODUCTION PROCESS- Implementing energy-efficient machinery and utilizing renewable energy sources, like solar panels, in manufacturing, By using this approach the TCI, Lowers energy costs, and reducing greenhouse gas emissions enhances operational efficiency while aligning with global sustainability standards, making the brand more attractive in eco-conscious markets.

3.) WASTE REDUCTION INTIATIVES- Tumandoks Craft Industries, Adopting lean manufacturing principles to minimize waste throughout the production process, including recycling scrap materials. Reducing waste not only decrease disposal costs but also allows the company to market itself as a leader in sustainable practices, appealing to environmentally aware consumers.

4.) ECO-FRIENDLY PACKAGING- Utilizing biodegradable or recyclable packaging materials to minimize environmental impact. Sustainable packaging enhances product appeal and differentiates TCI offerings in both local and international markets, particularly among eco-conscious consumers.

5.) PRODUCT LIFECYCLE MANAGEMENT- Designing products with their entire lifecycle in mind, ensuring they are durable, repairable, and recyclable. This approach promotes longer product life and reduced waste, attracting customers interested in sustainable consumption and enhancing brand loyalty.

6.) EMPLOYEE TRAINING AND ENGAGEMENT- Proving training on sustainability practices to employees and involving them in sustainability initiatives. Engaged employees are more likely to contribute innovative ideas for sustainability, fostering a culture of continuous improvement and enhancing overall operational efficiency.

ENHANCING COMPETITIVE ADVANTAGE

1.) Brand Differentiation-By positioning itself as a sustainable brand, Tumandok’s stands out in a crowded marketplace. This differentiation attracts eco-conscious consumers both locally and internationally, increasing market share.

2.) ACCESS TO NEW MARKET- Growing demand for sustainable products opens up new opportunities, especially in international markets where consumers are increasingly prioritizing environmentally friendly options.

3) REGULATORY COMPLIANCE- Proactively implementing sustainable practice helps Tumandoks stay ahead of regulations, reducing the risk of penalties and enhancing operational stability.

4.) CONSUMER TRUST AND LOYALTY- Committing to sustainability builds trust with consumers, fostering brand loyalty and encouraging repeat business, which is essential for long- term success.

5.)ATTRACTING PARTNERSHIPS AND FUNDING- Sustainability initiatives can attract partnerships with like-minded businesses and investors focused on environmental responsibility, providing additional resources for growth and innovation.

6.) ST SAVING- Sustainable practices often lead to operational efficiencies, resulting in lower costs in areas like energy consumption and waste management, thereby improving overall profitability.

By integrating these sustainability strategies into its process design, TCI not only minimizes its environmental impact but also enhance its competitiveness in an increasingly eco-conscious market. This alignment between sustainability and business strategy positions the company or long-term success, both locally and internationally.

QUESTION NO.3

Examine the role of innovation in TCI ability to adopt to changing consumer preferences and market demands. How has the company utilized design thinking principles to refine product offerings, and what implications does this have for its operational strategy moving forward?

ANSWER

Innovation plays a crucial role in TCI ability to adapt to changing consumer preference and market demands. By leveraging design thinking principles, the company can refine its product offering effectively.

ROLE OF INNOVATION

1.) RESPONSIVE PRODUCT DEVELOPMENT- Innovation enables TCI to quickly respond to emerging trends and shifts in consumer preferences, such as increased demand for sustainable customized products This responsiveness helps maintain relevance in the market, attracting a broader customer base.

2.) ENHANCE CUSTOMER ENGAGEMENT- Through innovative approaches TCI can engage customers more effectively, gathering insights that inform product development. This engagement builds brand loyalty and fosters a community around the brand, enhancing customer retention.

3.) COMPETITIVE EDGE- Continous innovation positions TCI industries ahead of competitors who may be slower to adapt, allowing it to capture market share in both local and international markets. A strong innovative stance reinforces the company’s market leadership and brand reputation.

URILIZING DESIGN THINKING PRINCIPLE

1.) EMPATHIZE- TCI need to conduct customer research, including interview and feedback sessions, to understand consumer needs and pain points. This deep understanding inform the design of products that resonate with customer, enhancing satisfaction.

2.) DEFINE- The company synthesizes research findings to clearly articulate the challenges it aims to solve with new products. A focused approach to problem- solving ensures that products meet specific market demands, reducing the risk of misalignment.

3.) PROTOTYPE-Rapid prototype allows TCI to create early versions of products that can be tested and refined based on user feedback. Iterative testing leads to higher quality and more desirable products, minimizing the chances of product failure.

4.)TEST- The company implementing a pilot launched to gather real-world feedback before fullscale production. Testing ensures that products meet expectations and helps identify areas for improvement, increasing the likelihood of success.

IMPLICATIONS FOR OPERATIONAL STRATEGY

1.) AGILITY AND FLEXIBILITY- An operational strategy rooted in design thinking allows one to remain agile and adapt quickly to changing market conditions and consumer preferences. This agility enhances the company’s ability to pivot when necessary, ensuring long-term relevance.

2.) CUSTOMER- CENTRIC FOCUS- By prioritizing insights throughout the product development process, TCI aligns its offering this actual consumer needs, A strong customer focus increases satisfaction and loyalty, driving repeat business.

3.)CONTINOUS IMPROVEMENT- The iterative nature of design thinking fosters a culture of continuous improvement within the organization. Regular refinement of processes and products leads to enhanced operational efficiency and innovation.

4.)RESOURCE ALLOCATION- Understanding consumer demands allows for better allocation of resources towards products that are likely to succeed in the market. More efficient use of resources can lead to cost savings and improve profitability.

5.) SUSTAINABILITY INTEGRATION- Incorporation of sustainability principles into design thinking can enhance product appeal in an eco-conscious market. Sustainable products can attract a broader audience and create a competitive advantage.

By embracing innovation and utilizing design thinking TCI is well-positioned to adapt to evolving consumer preferences and market demands. This approach not only refines its product offerings but also supports a robust operational strategy that promotes agility, customer focus, and sustainability, ensuring long-term success.

QUESTION NO. 4

Identify the key challenges TCI faces in integrating new technologies into its operations. Considering these challenges, what strategic recommendations would you propose for enhancing their process design and technology capabilities to ensure long-term sustainability and competitiveness?

ANSWER:

Integrating new technologies int TCI operations presents several key challenges. Addressing these effectively is crucial for enhancing process design and technology capabilities to ensure long-term sustainability and competitiveness. Here’s overview of the challenges and strategic recommendations;

KEY CHALLENGES:

1.) HIGH INITIAL COST- The upfront investment for new technologies can be substantial potentially straining financial resources, especially for a craft-based business.

2.) SKILL GAPS- Existing staff may lack the necessary skills to operate and maintain new technologies, which can hinder effective implementation.

3.)RESISTANCE TO CHANGE- Employees might resist adopting new technologies due to fear of job displacement or unfamiliarity with new systems.

4.) INTEGRATION COMPLEXITY- Ensuring that new technologies seamlessly integrate with existing processes and systems can be complex and time-consuming.

5.)ALIGNMENT WITH SUSTAINABILITY GOALS- Finding technologies that only improve efficiency but also align with sustainability objectives can be difficult.

STRATEGIC RECOMMENDATIONS

1.) PHASED IMPLEMENTATION OF TECHNOLOGIES- Introduce new technologies in stages, starting with pilot projects to assess feasibility and impacts before full-scale roll out. This approach minimizes risk and allows for adjustments based on initial feedback, easing the financial burden over time.

2.)INVEST IN TRAINING AND DEVELOPMENT – Develop comprehensive training programs to upskill employees in new technologies and processes, fostering a culture of continuous learning. Well-trained employees will feel confident and capable of using new technologies, reducing resistance to change and enhancing operational efficiency.

3.) ENGAGE EMPLOYEE IN THE CHANGE PROCESS- Involve employees in discussions about technology adoption and seek their input on potential solutions. This engagement fosters a sense of ownership and reduces resistance, encouraging a more collaborative approach to integration.

4.)SEEK PARTNERSHIP WITH TECHNOLOGY PROVIDERS- Collaborate with technology providers for training, support, and access to resources that facilitate smoother. Strategic partnerships can provide expertise and reduce the learning curve associated with new technologies.

5.)FOCUS ON SUSTAINABLE TECHNOLOGY- Prioritize the adoption of technologies that enhance sustainability, such as energy-efficient machinery or waste-reduction software aligning technology choices with sustainability goals not only minimizes environmental impact but also attracts eco-conscious consumers.

6.) IMPLEMENT ROBUST MONITORING AND EVALUATION- Establish metrics and feedback loops to monitor the performance of new technologies and their impact on operations regularly. Continuous evaluation allows for timely adjustments and improvements, ensuring that technologies are effectively supporting business goals.

7.)FOSTER AN INNOVATIVE CULTURE- Encourage innovation by creating platforms for employees to suggest ideas and improvements related to technology and processes. An innovative culture can lead to creative solutions for challenges faced during technology integration and improve overall competitiveness.

By addressing these challenges through targeted strategic recommendations, TCI can enhance its process design and technological capabilities. This proactive approach will help ensure long-term sustainability and competitiveness in a rapidly evolving marketplace.

Tumandok Crafts Industries has successfully integrated advanced lamination technology into its production processes, revolutionizing both product durability and operational efficiency. This technological advancement enhances product resilience by applying resin finishes to indigenous materials, making them more resistant to wear and damage, thus increasing their lifespan and boosting customer satisfaction. The lamination process also highlights the natural beauty of materials, much like the techniques used by high-end furniture manufacturers, resulting in visually appealing products. By adopting advanced lamination, TCI has streamlined its workflows, optimizing production time while minimizing waste. The precision offered by this technology allows for efficient material allocation, productive use of labor, and systematic overhead management. These improvements not only ensure consistent product quality but also position TCI to compete effectively in the global market. Furthermore, TCI remains committed to sustainability, incorporating powdered stone technology and upcycling coconut lumber to minimize waste. This eco-friendly approach mirrors global trends in the crafts industry, where businesses align with growing consumer demand for sustainable products. With reduced energy consumption and optimized output, TCI delivers high-quality, environmentally conscious products that delight customers worldwide.

Tumandok Crafts Industries (TCI) integrates sustainability into its process design through strategic initiatives that reduce environmental impact while strengthening its competitive edge. By prioritizing local sourcing, TCI minimizes carbon emissions associated with transportation and supports rural communities and artisans. A prime example is their use of indigenous materials, such as upcycled coconut lumber, which reflects a commitment to circular economy practices. Additionally, TCI employs powdered stone technology, utilizing by-products like sawdust and rice hulls to further reduce waste and conserve resources.

Incorporating state-of-the-art technology, TCI ensures that its products are not only high-quality but also eco-friendly, aligning with growing consumer demand for sustainable options. These efforts are complemented by ethical labor practices, providing local artisans with employment opportunities and helping preserve traditional craftsmanship, thus contributing to sustainable development goals.

TCI’s dedication to green practices resonates with environmentally conscious consumers, enhancing its brand image both locally and globally. With eco-friendly and ethically produced items featured in outlets like Kultura and international markets, TCI has successfully positioned itself as a leader in sustainability. This commitment differentiates the company from competitors, appealing to a broader consumer base and fostering brand loyalty. By embedding sustainability into its business model, TCI effectively taps into a market where eco-consciousness drives purchasing decisions, securing a strong foothold in the global market.

Tumandok Crafts Industries (TCI) leverages innovation by applying design thinking principles to remain responsive to evolving consumer preferences and market demands. Through this approach, TCI engages directly with customers, using their feedback to create products that are not only eco-friendly but also practical and appealing. By closely monitoring market trends and shifts in consumer behavior, TCI continually refines its offerings, much like global brands such as IKEA adapt their products to reflect changing consumer tastes.

This innovation-driven process enables TCI to introduce unique designs made from eco-friendly materials, such as banana fibers and seashells, catering to environmentally conscious consumers. Just as companies like Nike incorporate sustainable materials to meet the demand for greener products, TCI’s focus on sustainability sets it apart in the handicraft market. Design thinking also fosters creativity and operational flexibility, allowing TCI to quickly adapt to market changes and maintain competitiveness, similar to how smaller artisanal businesses differentiate themselves from mass-produced goods.

Looking ahead, TCI plans to prioritize customer-focused design, quick production, and innovative ideas, ensuring it continues to meet current market needs while anticipating future consumer demands. This strategy strengthens its position in both local and global markets, keeping its products fresh, sustainable, and highly attractive.

Tumandok Crafts Industries (TCI) faces challenges in adopting new technologies, including high costs, worker retraining, and potential disruption to existing processes. To ensure long-term sustainability and competitiveness, TCI should gradually introduce technologies like CNC (Computer Numerical Control) machining, which enhances precision, speeds up production, and reduces errors. Incorporating advanced edge banding machines will improve product finishing, durability, and reduce waste, aligning with TCI’s sustainability goals.

Investing in research and development, particularly in technologies like 3D printing, can enable TCI to create innovative, customizable designs and meet the growing demand for high-quality, eco-friendly furniture. Strengthening its digital presence through a robust e-commerce platform will further expand market reach.

Collaborations with technology providers and educational institutions can facilitate skill development, while lean manufacturing and continuous training for artisans can improve efficiency. These steps will help TCI stay competitive in a fast-changing market while maintaining its commitment to sustainability and craftsmanship.

Question 1:

Tumandok Crafts Industries is a social enterprise of handicrafts in Bago City, Negros Occidental, Philippines, that uses raw natural materials. These raw materials are transformed into sophisticated pieces that have graced the grand homes, offices, and commercial spaces around the world.

Everything made by Tumandok is a piece of art and love. Each one of these items was lovingly handcrafted by several skilled artisans, commencing over the course of many hours of labor in carefully arranging natural patterns, laminating, and buffing to reveal the organic raw materials’ natural beauty.

Tumandok Crafts Industries (TCI) is one example of successful process design and innovation in technology for the handicraft sector. This company utilizes eco-friendly native materials integrated with updated production systems to meet the increasingly in-demand green products market while advocating for local craftsmanship.

Tumandok Crafts Industries (TCI) is also a fully recognized social enterprise found in Bago City, Negros Occidental, Philippines. It produces some of the finest handicrafts created in the raw, natural resources of the Philippines. These materials are transformed meticulously into upscale pieces adorning luxurious homes, offices, and commercial spaces worldwide. Tumandok established its lamination factory in Barangay Central Ma-ao, Bago City. There were twelve workers at first and ₱50,000 in initial capital. This marked a significant milestone for them in their journey towards becoming one of the key players in the handicraft industry.

At the highest level, the Tumandok creations reflect artistry and devotion in that each one is literally handcrafted by artists who invest hours, days, and nights’ work painstakingly arranging natural patterns laminating and buffing the materials to highlight their inherent beauty.

TCI is an example of how traditional craftsmanship blends so organically with innovative process designs and technologies. In using sustainable indigenous materials combined with modern methods of production, the company not only caters to the growing market for ‘green’ products but also fights to preserve and upgrade local craftsmanship.

The advanced lamination technology enhances durability and aesthetic appeal in Tumandok’s products. The company uses a mix of local materials with resin finish to produce visually attractive and durable goods. The artisans are highly experienced in blending traditional methods with modern ways of production so as to produce high-quality piece works that acquire artisanal perfection in each and every product. Tumandok further utilizes powdered stone technology that mainly makes use of sawdust, rice hulls, and charcoal by-products that contribute to sustainability. This minimizes wastage and optimizes resource usage. This innovative approach enables Tumandok to produce rare products maintaining environmental standards.

Tumandok Crafts Industries aptly portrays how focussed sustainability, innovation, and communities can make the handicraft sector operationally successful. An effective use of indigenous materials, integration of modern technology, and high standards of ethics depicts the beauty of the company’s products and, at the same time positively contribute towards the economy of the locality while conserving resources. This makes their operational strategies, such as continuously improving and being responsive to market trends, put them in a comfortable position within a dynamic industry landscape, which ensures that they keep up with contesting challenges. As they move forward to more growth opportunities, Tumandok continues the handcrafts journeys by empowering communities while keeping up with high standards globally.

Sustainability relates very much to Tumandok’s production processes. An upcycle from coconut lumber, hitherto thought of as waste, into valuable raw materials is also well represented. It is indeed a very good example of the circular economy model, recycling materials to be turned into new resources that fit in with global initiatives to conserve waste. In addition, it focuses on local sourcing, minimizing carbon emissions in transporting products and enhancing the economy at the local level. It is expanded from materials to also ethical labor where it promotes local artisans for its designs. Reckon the principles, Tumandok meets the expectations of customers and connects to consumers with the rising concern of environment.

Question 2:

Tumandok Crafts would represented strategic export initiatives and partnerships with local markets that would depict a strong operational model that might be embraced as a prototype by other businesses looking to expand domestically and internationally.

True sustainability lies in the core of Tumandok production. By sourcing locally, it cuts on transportation emissions of carbon and supports the local economy at the same time. This is an innovation whereby coconut lumber, which would otherwise be waste, finds a commodity in raw materials. This is a perfect circular economy model wherein materials are used to recycle new products with the aim of sustaining global environmental initiatives aimed at reducing wastes. Tumandok is devoted not only to material sustainability but also on the level of ethical labor practice in the frame of supporting local artisans. It is in keeping with these dictates that Tumandok is able to meet the standards of expectations for customers and be resonant with consumers increasingly concerned with environmental impact.

Tumandok Crafts Industries has positioned itself in multiple markets. The local availability of their craft product is matched by international outreach. Their products sell in big local retail outlets such as Kultura and the OTOP outlet in Negros Occidental, thereby making these very accessible to local consumers. In addition, the export operations actively exhibit Filipino craftsmanship for international markets, thereby digging deeper into market reach. One good example of its community engagement efforts is the Negros Trade Fair, wherein it exhibits its products for the greater good of promoting these in its community while diversifying the market base to reduce dependence on a single market and to enhance business resilience during fluctuating global demand.

The company operates with continuous innovation in its operational strategy. The company continuously tracks market trends and shifting consumer demands for sustainable products; consequently, it modifies its production process. The principles of design thinking at Tumandok will push new ideas, prototype innovative offers, and evaluate market viability. For instance, they’ll introduce many new lines of designs that utilize a variety of materials like banana fibers and sea shells with an emphasis on sustainability. This strategy has bolstered adaptability, and it moves toward ability in meeting the growing expectations of the customer amidst a changing landscape of the industry.

Question 3:

Tumandok Crafts Industries Innovation Adaptation towards changing markets

It indeed provides the ground for flexibility in an organization like TCI to respond to shifting consumer preferences and needs for goods and services in the market. Company-sponsored innovations indeed have an impact on continuous exploration of new technologies that are available, as well as staying ahead of the curve on product development.

Design Thinking and Product Refining

It has, through the design thinking principles, enabled TCI to change its product offerings as a path to solving problems for humans. Design thinking emphasizes empathy, ideation, prototyping, and testing. Through this channel, TCI has managed to:

Understand consumer needs: the research conducted by the company in understanding what consumers prefer, what they desire, and what pains them has been valuable to inform product development that resonates well with the target market.

Generative imagination: TCI has been inventive by inventing culture, opening space for the minds of employees to generate ideas about the product and process. Such creativity led to some unique products and new offerings.

Prototyping and testing: The Company produced several prototypes of newly designed products to check and verify the feasibility, functionality of the products, and their appeal. It is an iterative designing process; therefore, TCI was sure that its designs were acceptable and products met the desires of customers.

Operational Strategy

Several implications arise with the integration of design thinking in TCI’s operational strategy:

The company would gain much more agility, as it could respond quickly to market trends and consumer feedback by shifting its product offerings in response to their changing demands.

Satisfaction with customers would also be improved as the products are designed for the customer, giving a much better probability of being aligned with the customer’s needs and expectations and satisfying him more.

Innovation advantage: Innovation can provide TCI with a competitive advantage since the products offered by TCI become differentiated from those offered by other competitors.

Efficiency Increased: Design thinking may lead to more efficient production processes because of catching areas where there are lapses in the system and smoothing out operations.

To keep carrying its success, TCI should invest in research and development so that it becomes an explorer of new technologies and raw materials. At the same time, it should encourage innovation culture at the firm level so that there are always employees from each tier encouraging creative thoughts and risk-taking. If TCI dedicates itself to its core competency in design thinking and innovation, it will sustain itself for long periods and rise.

Question 4.

Strategic Recommendations: Process Design and Technological Capabilities for TCI to Remain Sustainable and Competitive

Considering the challenges of Tumandok Crafts Industries (TCI) like fluctuations in raw materials, competitiveness against mass-produced products, and strengthening its online presence, the following strategic recommendations can be avowed to enhance process design and technological capabilities:

1. Diversify the Supply Chains and Explore Alternative Materials

Alternative suppliers: TCI should identify those suppliers who possess raw materials in good quality on the cost-friendly side. They may look for an alternative supplier which can be domestic and international.

Research for an alternative material: The company should study to know if there are alternatives that have better availability or are cheaper than the ones currently being used. These may include recycled materials, local substitutes, and synthetic materials that closely mimic the current characteristics.

2. Invest in Technology and Automation

Automate: TCI should outline the areas of the process that can be automated in respect to cutting, assembly, or finish. It can shave off labor costs, while raising the efficiency of most production processes with consistency.

Invest in 3D Printing: Through 3D printing, TCI can create custom molds, prototypes, and even print a finished product. This gives it the ability to cut down on lead time, personalize, and even capitalize on the newness of design.

3. Increased Digital Competencies

E-commerce should be strengthened: TCI must invest in a robust e-commerce platform to expand its customers and strengthen online sales. It can optimize its website, utilize proper digital marketing strategies, and integrate with online marketplaces.

Utilize social media: The business should avail itself of all social media to engage with customers, show the products, and create an awareness for the brand. This would eventually drive people to the site and boost online sales.

4. Foster a Culture of Innovation

Foster creativity: TCI should maintain a working environment that ensures innovation and creativeness. This could be through professional development opportunities for employees, inviting innovative ideas, and rewarding them.

Engage externals: The firm should form external alliances with designers, artists, as well as other firms to bring in new thinking and enter into new markets.

5. Human Resource Development Training: TCI must put in a good amount of training. The employees must be well-equipped in response to fast changes. New technologies, sustainability practice, customer care, and so on.

A positive work culture should be created where the employees will be encouraged in engaging and satisfied in their work. This may improve productivity, reduce turnover, and attract high-quality talents.

By implementing the above strategic recommendations, TCI would enhance its process design and technologic capability, improve its long-term sustainability, and thus remain competitive in the global marketplace.

With the growing emphasis on sustainability, modern consumers are increasingly opting for eco-friendly furniture. Thus, Tumandok Craft Industries is among those who really in to technology integration while promoting sustainability. The primary appeal of lamination technology stems from its durability, designed to withstand external factors or to different environment conditions,, this helps prolong the lifespan of furniture, ensuring that it endures overtime. Lamination technology suits to business which are environmentally conscious, align with shift towards sustainability. By selecting laminated furniture from TCI, consumers from local and even international are not only choosing durability and style but also contributing to a greener future. This sustainability factor adds to their attractiveness, making laminates a thoughtful choice for contemporary furniture design. The use of this technology goes beyond a passing trend: it reflects evolving expectations for durability, aesthetics and environmental responsibility in the future industry. Presently, people are now into local products not only because they wanted to support local but because industries’ like TCI is now integrating technology which even make their products a top of the line and that is what people of nowadays need, TCI’s laminate are at the forefront of fulfilling these needs. By redefining both longevity and style, TCI is establishing new benchmarks for future standards.

We cant deny the fact that technology plays a vital role in business success. With technology integration, TCI significantly improve crafting design and efficiency. Alongside the traditional wood that we used to see as a raw materials in furniture making, coconut lumber, by products like sawdust, rice hulls and charcoal has come to the picture, who would have thought that these materials typically regarded as waste materials can be converted to a beautiful furniture that we can be proud of as a Negrosanon. Clearly, through the integration of technology, TCI able to produce product that aligns with the increasing demands of customer and promoting sustainability at the same time, TCI is committed in serving Negrosanon a local made furniture but with globally accepted durability and quality.

Innovation happens if there are changes in the product to make it valuable. Innovation means adapting to the business environment, adapting the new market trends and customer preferences. Tumandok shos that resiliency and adaptability through the test of time and through innovation TCI, able to stay and even improve their product design and efficiency, technology allows TCI stay competitive amidst the challenges. What’s good about TCI its that of its design thinking principle in which focuses on a collaboration on how real users think, feel and behave. This is a human centered process which manufacturer empathize, define ideas ,proto type and testing, this is an example of QUALITY FUNCTION DEPLOYMENT a method in which transforms user demands into design quality, to deploy functions forming quality and to deploy methods for achieving the design quality into subsystems and component parts and ultimately to specific elements of the crafting process.

No single business succeed without faxing challenges and Tumandok Crafting Industries is not an exception to those, among the challenges are rising coast of materials especially those that are imported form other countries, the ever changing market trends and of course competition and a massive produced local and international goods that may affect pricing structures of TCI, and also integration of technology entails expenses, this could result to incurring additional expenses on purchasing new technology, training of employees handling the technology, maintenance and all. Nevertheless, TCI was able to catch their niche and able to put their product on top.

In order to better address the challenges and enhance the process design to ensure long term sustainability and competitiveness, TCI may opt to integrate AI or AUTOMATION, to streamline the process and lessen human error thus increasing efficiency. They may also adopt cleaner production techniques such as low energy production processes, reducing greenhouse gas emissions and energy consumption. establish key performance indicators for sustainability such as energy consumption, waste reduction and water usage. To stay ahead of the competitor, TCI must not stop innovating, employs the KAIZEN and JIT principle

1. Impact of Advanced Lamination Technology on Production Processes

The integration of advanced lamination technology has significantly transformed Tumandok Crafts Industries’ production processes. By incorporating this technology, Tumandok has improved both operational efficiencies and product quality. The use of lamination has enhanced product durability and aesthetic appeal, blending traditional craftsmanship with modern methods to create resilient and visually stunning items. This has led to greater customer satisfaction and wider market appeal, both locally and internationally. Additionally, lamination technology supports sustainability goals by optimizing resource utilization and minimizing waste through the upcycling of materials like coconut lumber, aligning Tumandok with global sustainability standards. These innovations position the company favorably within the competitive handicraft industry, meeting the growing demand for eco-friendly, high-quality products.

2. Sustainability Strategies and Competitive Advantage

Tumandok Crafts Industries integrates sustainability into its process design through several strategies:

Local sourcing reduces carbon emissions and supports the local economy by utilizing indigenous materials.

Upcycling of coconut lumber minimizes waste and supports a circular economy model, reducing environmental impact while creating valuable products.

The use of powdered stone technology ensures resource efficiency, further minimizing the company’s environmental footprint.

These sustainability strategies not only reduce Tumandok’s environmental impact but also enhance its competitive advantage. By aligning with eco-conscious consumers, Tumandok strengthens its brand reputation, making it a leader in both local and international markets. This strategic focus on sustainability and quality craftsmanship drives long-term growth and positions Tumandok as a global leader in sustainable handicrafts.

3. Role of Innovation and Design Thinking

Innovation is at the core of Tumandok’s ability to adapt to changing consumer preferences and market demands. By leveraging design thinking principles, the company has refined its product offerings to stay aligned with sustainability trends while maintaining regional craftsmanship. Tumandok integrates advanced technologies like lamination and powdered stone, while upholding its commitment to upcycling and ethical labor practices. These innovations improve both product durability and visual appeal, allowing Tumandok to meet evolving consumer expectations sustainably.

Tumandok’s design thinking approach fosters continuous innovation and market-driven product development. For example, the company plans to introduce new design lines using innovative materials such as banana fibers and sea shells, enhancing operational adaptability. This strategy ensures that Tumandok remains agile in the face of market changes, maintaining a competitive edge while prioritizing sustainability, supporting the local community, and reducing environmental impact.

4. Key Challenges and Strategic Recommendations

Tumandok faces several challenges in integrating new technologies, including rising raw material costs, particularly for imported resin, and competition from mass-produced goods. Additionally, the company’s artisans require further training to adopt new technologies effectively. To address these challenges, the following strategic recommendations are proposed:

Explore Alternative Materials: Invest in research and development of locally sourced materials to reduce reliance on costly imports like resin.

Invest in Advanced Technologies: Adoption of 3D printing and other affordable technologies could reduce production costs and foster innovation, allowing Tumandok to develop intricate designs more efficiently.

Strengthen Digital Presence: Expanding into e-commerce platforms will increase Tumandok’s visibility in international markets, especially among consumers seeking eco-friendly, artisanal products.

By enhancing their process design and adopting new technologies, Tumandok can reduce production costs, expand product offerings, and remain competitive in the global handicraft market. Continuous employee training and collaboration with academic institutions will ensure high-quality craftsmanship, while a stronger online presence will broaden the company’s market reach.

In conclusion, Tumandok’s focus on innovation, sustainability, and strategic technological adoption will ensure long-term sustainability and competitiveness, reinforcing its role as a model for sustainable handicrafts.